| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click to enlarge) |

|

RS-CFO

2

|

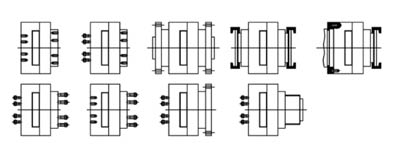

Double Plate Hydraulic Screenchanger

CFO2 is characterised by a flow channel divided in two

different filtering cartridge slide plates that

interchangeably slide open or close the channel where material flows.

The slide plates movement is made by cylinders

actuated by a hydraulic power unit. Stop micro

switches ensure the accuracy of their movement.

This screenchanger offers the advantage of avoiding

interruptions in the production process. For this

reason, it is suitable for high productivity and continuous

cycle plants.

CF2 can be installed on extruders with screw diameter

range from 30 mm. to 250 mm. and over. |

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

|

|

RS-CFO

1

|

Mono Plate Hydraulic Screenchanger

CFO1 is a mono plate screenchanger with a slow slide

plate movement (made possible by a cylinder activated

by a hydraulic power unit) or with a fast slide plate

movement (performed by a cylinder actuated by a hydraulic power unit

and a pressure accumulator). The latter solution

allows the screenchanger to work without any interruption

of the production process.

This screenchanger can be used on any extrusion

line and extruders with screw diameter range from

30 mm. to 250 mm. and over.

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click

to enlarge) |

|

RS-CFMP

|

Manual Screenchanger with Lever Hydraulic Pump

CFMP is a mono plate screenchanger with the movement

of the slide plate performed by a manual lever hydraulic

pump. Ideal for reduced dimensions and contained

costs multi-layer co-extrusion lines, can be mounted on extruders

with screw diameter range from 30 mm. to 120 mm.

and over. When replacing the filtering cartridge,

this screenchanger requires a stop in production.

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click

to enlarge) |

|

RS-CFMV

|

Screenchanger with Handwheel Screw Movement

CFMV is identical to CFMP, the only difference is made

by the mechanical sliding of the plate, performed

using a handwheel screw.

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click

to enlarge) |

|

RS-CFL

|

Screenchanger with manual lever

The screenchanger of the CFL set respond to two important

industrial needs:

- Very low power consumption:

- Minimum space required, as they have been projected

in order to have an easy placement, also looking

to ergonomics and the possibility of any assistance by technicians

and operators.

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click

to enlarge) |

|

RS-DIVERTER

VALVE

|

Diverter

Valve

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

(click

to enlarge) |

|

|

©

Flow channels

©

Deflector blocks

©

Mono-layer column heads

©

Mono-layer extrusion heads

©

Co-extrusion heads up to diameter of 700 mm.

OUR SCREENCHANGERS CAN BE MOUNTED ON SINGLE SCREW

EXTRUDERS OR TWIN SCREW EXTRUDERS

VARIOUS TYPES OF CONNECTION BETWEEN SCREENCHANGERS

AND EXTRUDERS

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

|

|

|

| Screw Diam.

Extruder |

Diam. Breaker |

Capacity KG.

HOUR* |

| 30/35 |

50 |

65 |

| 40/50 |

70 |

130 |

| 55/65 |

90 |

225 |

| 70/75 |

100 |

270 |

| 80/90 |

120 |

385 |

| 100/105 |

160 |

710 |

| 120 |

180 |

830 |

| 130 |

200 |

1170 |

| 150/160 |

230 |

1540 |

| 180 |

250 |

1750 |

| 200/A |

300 |

2600 |

| 200/B |

300 |

2080 |

* The capacity is calculated for productions of LDPE

with a working pressure of 200 BAR.

For any other material and for higher pressure, please

contact our technical department.

|

|

| ––––––––––––––––––––––––––– |

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––– |

|

| |

|

|